All equipment manufactured by Neuberg is customised according to customer requirements.

High standards of quality and robustness, safety and efficiency, durability and ease of maintenance.

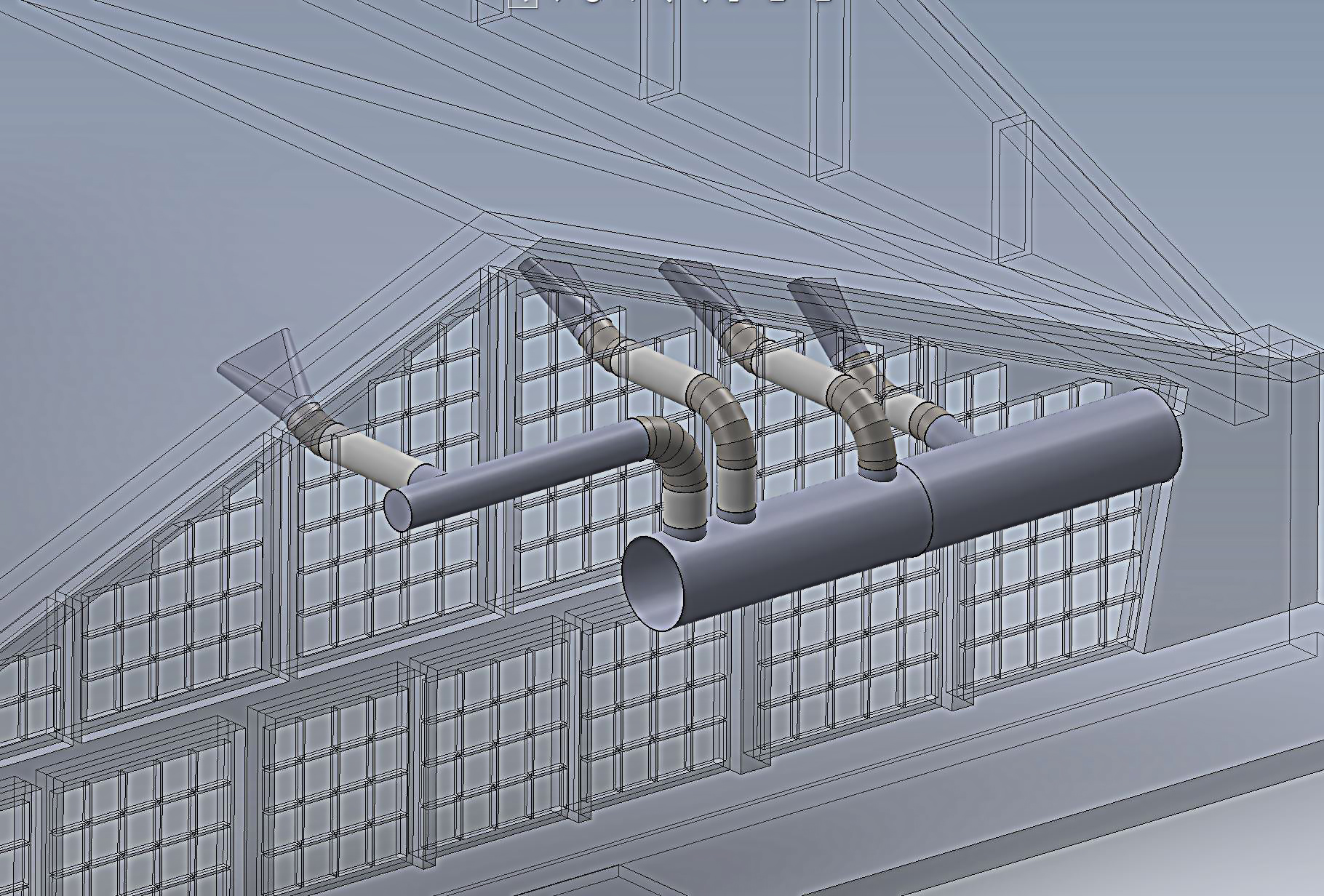

CHOPPER EVO fans

Designed for material transport

Available with radial blades and equipped with serrated or smooth blades

Suitable for use with several types of waste products

Pulley or direct drive with easily accessible lubrication system

Equipped with an inspection door on the housing

Fixed or adjustable inlet nozzle

High performance

Fully automatic, designed for continuous high-speed filtration

Enable high efficiency filtration by cleaning the filter media with pneumatic backwashing

Static equipment for air-material separation in pneumatic conveying systems

Consisting of a box with an inclined mesh inserted

Used in paper and cardboard waste transport installations, to feed compactors, bale presses, press containers, pulper and other waste collectors

Mobile suction and filtration system, supplied in single or multi-element configuration

Suction and filtration capacity of up to 30,000 m³/h in a compact, roll-off unit the size of a container

Can be transported by any towing vehicle and installed in the area in front of the designated suction/filtration site on a flat surface

Used in numerous applications to manage air circulation: this is thanks to a high-efficiency fan, installed inside the application cabin, which generates a flow of air that is subsequently purified by a dedusting filter, and emitted back into the atmosphere

Its flexibility allows various contexts of use:

- confined places such as silos, tanks, boilers (with specific directives)

- places for sandblasting tanks or cisterns

- demolitions

- on naval transports

- at customers in non-European countries where quick dismantling and recovery might be useful