ATEX

EXPLOSIVE ATMOSPHERES

An explosive atmosphere is a mixture with air, under atmospheric conditions, of flammable substances in the form of gases, vapours, mists or dusts.

ATEX STANDARDISATION

The objective of Neuberg Srl is to limit the considerable costs to be incurred in order to comply with ATEX regulations due to the identification of ‘atex zones’

THE JKE RANGE OF FILTERS

The fabric bag filters of the JKE range are designed in compliance with the European Union’s ATEX- directive 99/92/EC and 2014/34/EU.

What is ATEX?

Derived from the words ATmosphères and EXplosibles, ATEX is the conventional name for two European Union directives:

2014/34/EU for the regulation of equipment intended for use in potentially explosive atmospheres.

The directive is aimed at manufacturers of equipment intended for use in areas with potentially explosive atmospheres, and manifests itself in the mandatory certification of these products.

Directive 94/9/EC is repealed by this with effect from 20 April 2016.

99/92/EC for the safety and health of workers in explosive atmospheres

The directive applies in potentially explosive atmospheres, where certified plant and equipment is put into operation, and is therefore aimed at users.

A potentially explosive atmosphere exists when a mixture of air gases, vapours, mists or dusts combine in a way that can ignite under certain operating conditions.

Equipment and protective systems intended for use in potentially explosive atmospheres (ATEX) cover a range of products, including those used on fixed offshore platforms, petrochemical plants, mines and mills, among others.

Explosive Atmospheres

The Atex Directives (*) lay down the essential health and safety requirements, and entrust harmonised European standards with the task of giving technical expression to the relevant requirements contained therein.

Both Directives apply to equipment and protective systems intended for use in potentially explosive atmospheres within the EEA (European Economic Area) territory.

The absence of the two requirements (potentially explosive atmosphere and location of installation within the territory of the EEA) makes it inapplicable.

Employers (ATEX 99/92/EC) and manufacturers of equipment that can be installed in such areas (ATEX 94/9/EC) are obliged to comply with these regulations concerning the potentially explosive environment.

The ATEX Directive is mandatory for all equipment and protective systems placed on the market or in service after 30 June 2003.

(*) Standards update

The consolidated text of the ATEX Directive 94/9/EC

The new ATEX Directive 2014/34/EU on equipment and protective systems intended for use in potentially explosive atmospheres is aligned with the ‘new legislative framework’ and will be applicable as of 20 April 2016.

An ATEX Directive transition guidance document from 94/9/EC to 2014/34/EU is now available on the official website, with a list of frequently asked questions and answers.

The adaptation to the Atex standard

The objective of Neuberg Srl is to limit the considerable costs to be incurred for the ATEX standardisation due to the identification of ‘ATEX zones’ by providing, in full compliance with the ATEX regulations 2014/34/EU (94/9/EC) and 99//92/EC:

- centralised dedusting systems (treatment of dust emissions)

- fume extraction (gas emissions, solvents)

Neuberg Srl is supported by companies and organisations in the sector in carrying out:

- explosive dust analysis

- ATEX analysis of installations

Furthermore, it guarantees the conformity of its equipment with the regulations.

The ATEX Directive is mandatory for all equipment and protection systems placed on the market or in service after 30 June 2003.

Protections applied to JKE filters

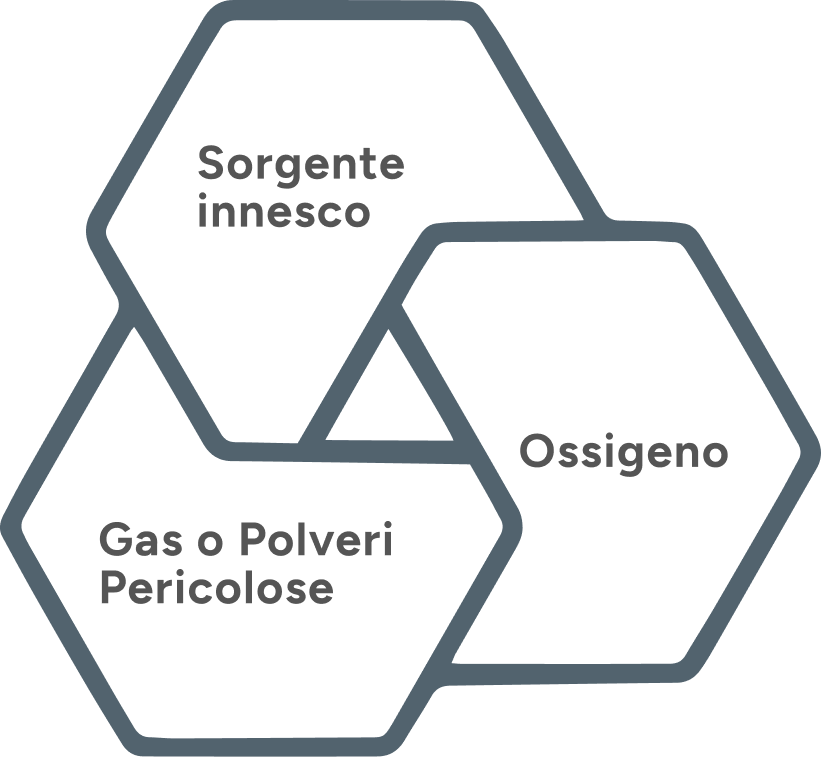

According to the European Union Directive 2014/34/EU (94/9/EC) the occurrence of explosive events is subject to the coexistence of essential conditions.

Risk reduction is only possible when all essential conditions for triggering a dust explosive event are under control and their occurrence simultaneously prevented.

The filters in the JKE range are designed in accordance with the above:

- choice of materials

- structural calculation

- use of ‘blast panels’ (venting) or other prevention and suppression systems

The choice of materials and structural calculation have been carried out using finite element models of the structure by a technical studio specialised in these types of calculations (ref. Italian standard CNR UNI10011/88).

Anti-exhaust panels or venting systems prevent the formation of excessive overpressure inside the filters. Fundamental to the effectiveness of the venting action is the correct sizing of the panel (shape, structure) in relation to the conformation of each individual filter.